Development of innovative products based on dried organically cultivated Lion's Mane mushroom (Hericium erinaceus) with high quality and functional parameters

- R&D Team Implementing the Operation:

Research and development work will be conducted by the University of Economics in Poznań (UEP). The team will include: Marta Ligaj (Dr. hab. in economics specializing in commodity science, Institute of Quality Sciences UEP, previously manager of 3 R&D projects), Sylwia Sady (Dr. in management and quality sciences, Institute of Quality Sciences UEP), Bogdan Pachołek (Dr. hab. in economics specializing in commodity science, Institute of Marketing UEP, director of food products at the Research and Development Center of UEP Special Purpose Company Ltd.). Research and development work will also be conducted at the Project Leader's facility. The team will include: Marek Siwulski (Prof. of natural sciences, specialist in edible and medicinal mushroom cultivation, Faculty of Agriculture, Horticulture and Bioengineering, University of Life Sciences in Poznań), Alina Matuszak-Flejszman (Prof. of social sciences, director of the Institute of Management UEP, Head of Quality Management Department, practitioner in implementing quality, environmental and safety management systems, expert in science and economy NCBR), Alfred Błaszczyk (Prof. UEP, Dr. hab. in economics specializing in commodity science, Institute of Quality Sciences UEP, production technologist, expert in science and economy in NCBR), Eng. Wojciech Dopierała (technical specialist, professional experience in implementing new products and technical solutions at Novazym company).

- R&D Team Experience:

- assessment of the impact of Lion's Mane mushroom cultivation conditions on its properties (Siwulski and Sobieralski, 1998; Siwulski et al. 2009; Siwulski and Zawirska-Wojtasiak, 2007) - assessment of antibacterial properties of natural substances (Ligaj et al. 2020) - assessment of antioxidant activity using electrochemical methods (Ligaj et al. 2021) - assessment of antioxidant activity of chokeberry pomace (Sady, Błaszczyk et al. 2021) - fruit processing by-products in food design (Pachołek, 2019) - research on the effectiveness and efficiency of management systems (Matuszak-Flejszman, 2019) - proprietary environmental management system (Matuszak-Flejszman, 2016) The project is based on research results indicating a wide range of health-promoting properties of Lion's Mane mushroom (Jiang et al. 2016, Diling et al. 2017a, b, He et al. 2017, Li et al. 2018, Hetland et al. 2020, Yang et al. 2021). The project also intends to use research results on the antimicrobial effects of cold plasma (Katsigiannis et al. 2022, Veerana et al. 2022), which will be used for decontamination of the cultivation hall and disinfection of the pilot technological line intended for the production of dried mushrooms and products based on dried mushrooms.

- List of R&D Work and Results of the Operation:

As part of the operation, development work has been planned for the following areas: - development of an innovative method for organic cultivation of 4 varieties of Lion's Mane mushroom (controlled cultivation conditions, substrate modification, disinfection of cultivation rooms), certified fruiting body testing - development of an application facilitating the farmer's optimization of Lion's Mane mushroom cultivation conditions (as a result of the operation, a computer application will be developed, based on the use of Excel software, which is a tool enabling the handling of spreadsheets and analysis of entered data, which will enable the farmer to monitor the yield of Lion's Mane mushroom depending on cultivation conditions, it is intended to achieve a yield increase of at least 30% compared to the cultivation conditions currently used in the farmer's farm) - development of a prototype device design for microencapsulation of chokeberry pomace with a disinfection module - optimization of chokeberry pomace microencapsulation technology using spray drying, - development and implementation of a pilot production line for organic dried Lion's Mane mushroom fruiting bodies (device prototypes: dryer, grinder, equipped with disinfection modules), - design and implementation of a proprietary integrated food safety, quality and environmental management system, - development of two innovative organic products containing dried Lion's Mane mushroom fruiting bodies standardized for β- and α-glucan content and microcapsules from chokeberry pomace.

- Research Methodology:

- assessment of the impact of cultivation conditions on yield level and content of biologically active compounds will include the introduction of 4 varieties for cultivation, which will be grown under variable temperature and humidity conditions on various substrates based on sawdust and by-products, including coffee bean husks, plant pomace; fruiting bodies will be tested for antioxidant properties using DPPH and ABTS methods in QUENCHER technique, electrochemical index using voltamperometric techniques and β- and α-glucans using enzymatic tests and spectrophotometric methods; fruiting bodies of 4 varieties will be evaluated for sensory quality using sensory profiling method; - optimization of preparation of microcapsules from freeze-dried chokeberry pomace with a shell based on kuzu starch and inulin will include optimization and validation of the microcapsule production process using statistical experimental design methods (DOE); microencapsulation parameters such as temperature, raw material concentrations will be selected; the following will be analyzed: microcapsule size, water content and antioxidant properties (DPPH, ABTS, voltamperometric methods), microbiological purity; obtained microcapsules will be characterized using methods such as: thermal (DSC), SEM imaging, FTIR spectroscopy and dialysis (release of bioactive substances); - optimization of conditions for preparing dried Lion's Mane mushroom fruiting bodies with high quality parameters will include assessment of the impact of temperature and drying time and the use of electroporation and cold plasma phenomena on the antioxidant properties of the dried product (DPPH and ABTS method research), electrochemical index, glucan content and microbiological quality; - optimization of preparation of products based on dried Lion's Mane mushroom fruiting bodies and microcapsules from chokeberry pomace with high quality and functional parameters will include determination of antioxidant properties (DPPH and ABTS methods), electrochemical index using voltamperometric techniques, β- and α-glucans, number of microorganisms; research will be performed for products after their production and during storage studies to determine the stability of their quality and functional parameters.

- List of Innovations Resulting from the Operation:

a) Product innovations: - range of 4 varieties of Lion's Mane mushroom, including 3 new, previously uncultivated varieties, which will be characterized in terms of: β- and α-glucan content, antioxidant activity, sensory characteristic profile; - fruiting bodies of Lion's Mane mushroom standardized for β- and α-glucan content, selected for the production of dried products and products based on dried mushrooms, characterized compared to previously cultivated ones by 30% lower spore content in fruiting bodies, at least 20% higher β- and α-glucan content, at least 15% higher antioxidant activity; - dried Lion's Mane mushroom fruiting bodies standardized for β- and α-glucan content, which compared to standard production methods, will be characterized by high microbiological purity (reduction of mold count and total microorganism count in dried product by at least 30%, E. coli, Staphylococcus aureus, Listeria monocytogenes, Salmonella absent in 10 g of dried product), increase in β- and α-glucan content by at least 10%, increase in antioxidant activity by at least 10%; - encapsulated dried Lion's Mane mushroom standardized for β- and α-glucan content, which compared to standard production, will be characterized by high microbiological purity (E. coli, Staphylococcus aureus, Listeria monocytogenes, Salmonella absent in 25 g of ground dried product), β- and α-glucan content higher by at least 30%, antioxidant activity higher by at least 25%; - product containing encapsulated dried Lion's Mane mushroom and microcapsules from chokeberry pomace standardized for β- and α-glucan content, which compared to standard production, will be characterized by high microbiological purity (E. coli, Staphylococcus aureus, Listeria monocytogenes, Salmonella absent in 25 g of ground dried product), β- and α-glucan content higher by at least 25%, antioxidant activity higher by at least 30%. b) Technological innovations: - innovative method of organic Lion's Mane mushroom cultivation through appropriate selection of cultivation substrates, controlling cultivation conditions and including a cultivation hall environment purification system using cold plasma generators, which will allow for reduction of mold count in cultivation hall air by at least 50%, reduction of total microorganism count in cultivation hall air by at least 60%, increase in yield by at least 30%; - innovative technology for production of organic dried Lion's Mane mushroom fruiting bodies using a pilot production line containing developed device prototypes (dryer and grinder equipped with disinfection module) and PEF generator will provide the following benefits: increased bioavailability of active compounds, high microbiological safety (reduction of mold count and total microorganism count in dried product by at least 30%, E. coli, Staphylococcus aureus, Listeria monocytogenes, Salmonella absent in 10 g of dried product), possibility of product standardization for β- and α-glucan content; - innovative technology for producing organic products based on dried Lion's Mane mushroom using a pilot production line containing developed device prototypes (encapsulator equipped with disinfection module) will provide the following benefits: high microbiological safety (E. coli, Staphylococcus aureus, Listeria monocytogenes, Salmonella absent in 25 g of ground product), possibility of obtaining homogeneous microcapsule structures with a diameter of 20-50 micrometers, possibility of product standardization for β- and α-glucan content, possibility of producing stable products with high functionality. c) Organizational innovation: Mykoherbals company will introduce improvement in management regarding ensuring high quality of processes and products and minimizing negative environmental impact. The innovation will include processes related to designing and implementing activities within which innovative products will be created, i.e., dried Lion's Mane mushroom fruiting bodies and products based on dried mushrooms. One of the latest enterprise management concepts will be applied. The essence of innovation lies in a comprehensive approach to managing enterprise resources through integration of components forming its entirety, into a coherent quality, safety and environmental management system allowing maximum limitation of human role in these processes, which should be limited to decision-making processes. This concept uses and combines individual components of previously known management concepts, including the Business Process Reengineering (BPR) concept, whose essence is thorough reconstruction of processes occurring in the enterprise to improve its operational efficiency. Another implemented concept will be the TQEM (Total Quality & Environment Management) concept, whose essence is to manage the organization in such a way that every aspect of activity is implemented with consideration of pro-quality and pro-environmental perspective. It is also worth noting elements of the Green Lean Management concept, whose authors pointed to the need for lean organization management. Its goal is to avoid waste and strive for rationalization of organizational functioning and use of available resources. All this will consider activities aimed at minimizing negative environmental impact. Proprietary management methods will be applied based on the use of Green Lean Management tools such as: 5S, FMEA, QFD, VSM. Implementation of the proprietary management system in the Applicant's company will include specific design of processes occurring in it to develop applicable procedures and control and monitoring tools used in such a way that operational activity management within process implementation proceeds smoothly and effectively. Such an approach will increase Mykoherbals' operational efficiency because individual departments will perform specific management procedures mostly without the need to consult with management. The proprietary system for integrated food safety, quality and environmental management will be characteristic only for Mykoherbals Ltd. and has not been implemented in any other organization to date. The introduced methods will contribute to guaranteeing high quality and safety of products while considering minimal environmental impact resulting from the operation. Moreover, as a result of implementing the proprietary management system, resources will be optimized through effective process management, organizational functioning efficiency will improve through efficient and effective management, operational costs will decrease through waste elimination, operational process productivity and efficiency will increase, which will result in increased sales revenue, increased profitability, improved Mykoherbals image and increased competitiveness.

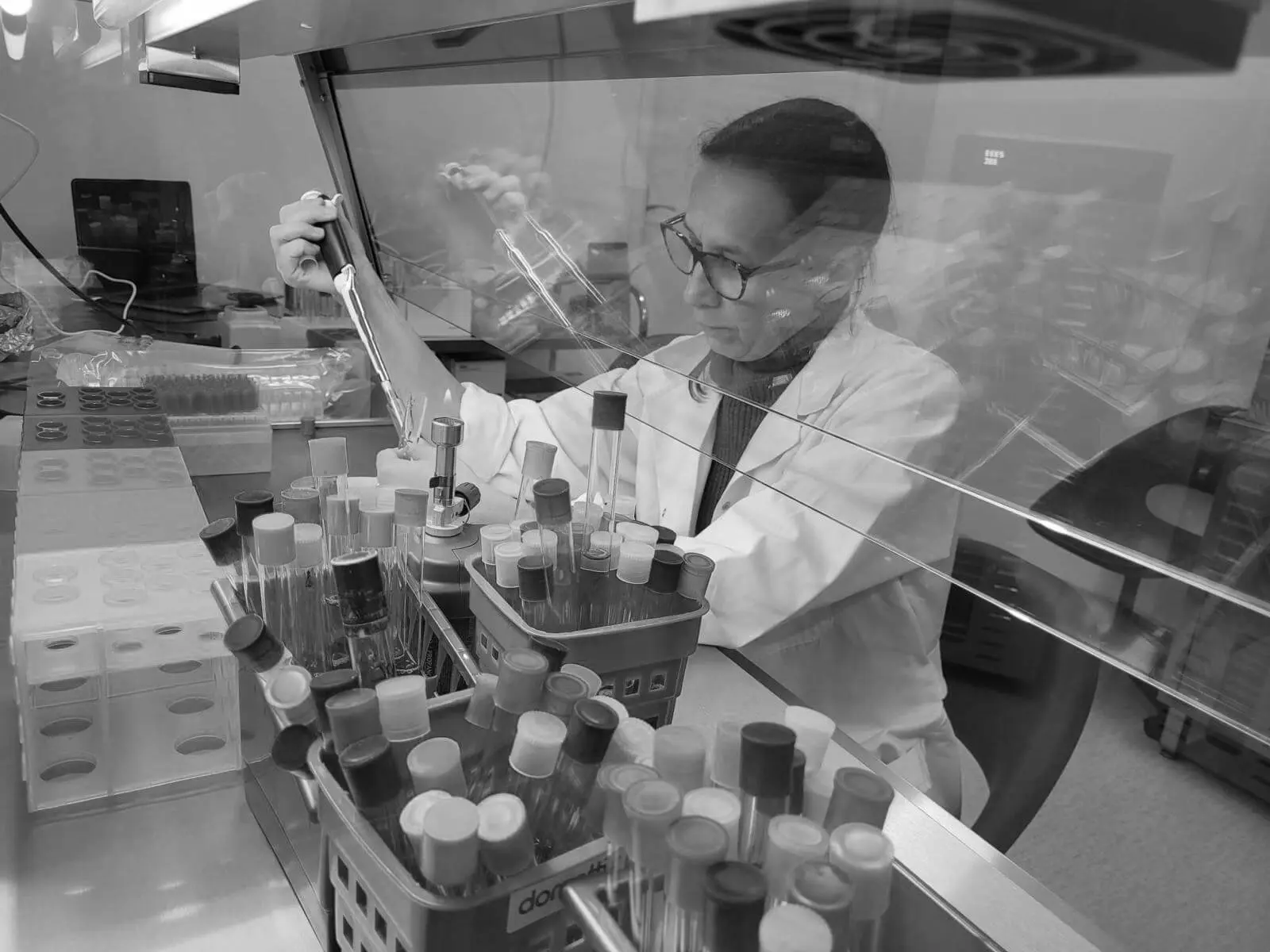

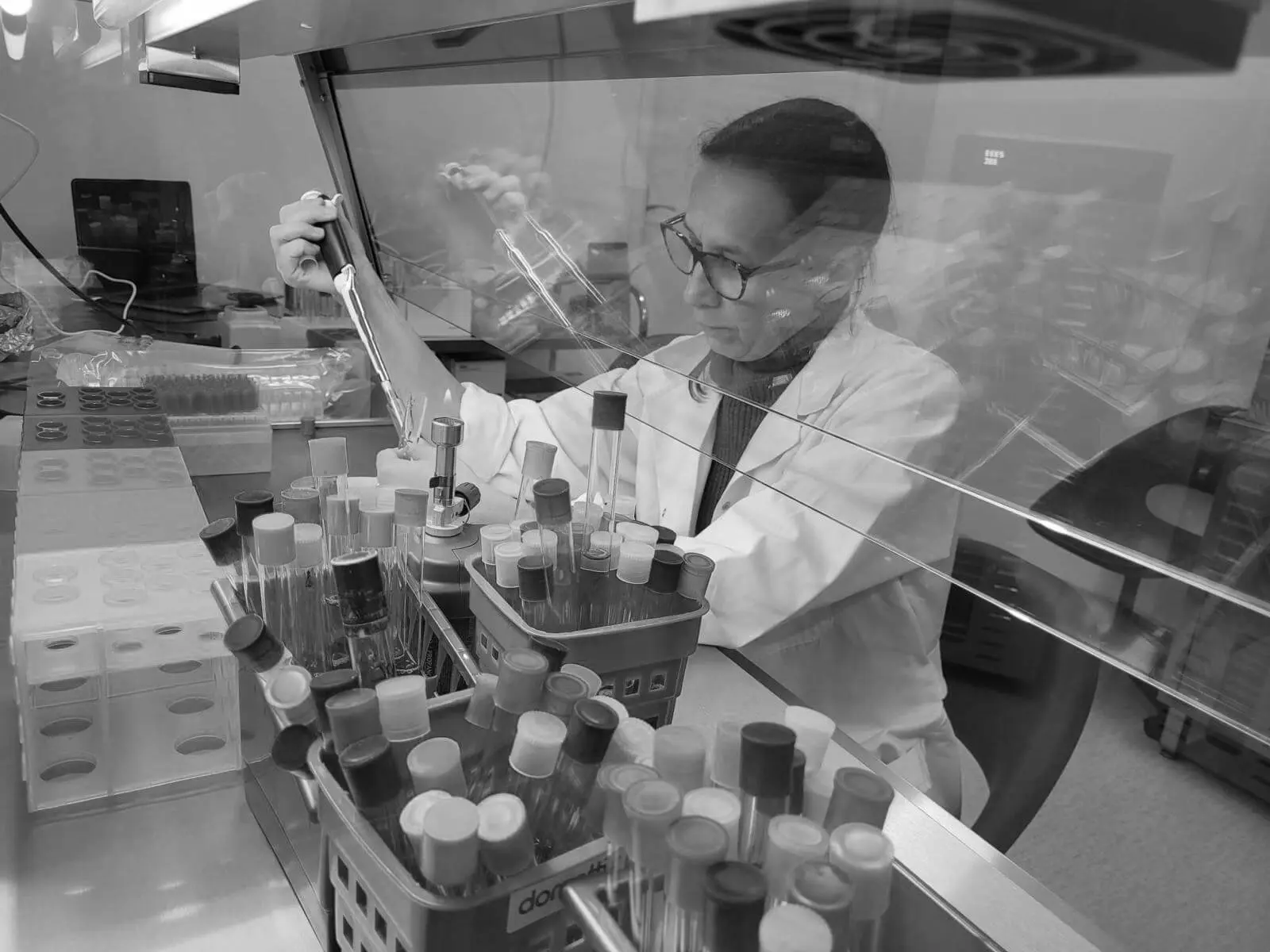

Laboratory

Source: own archive